When you buy a TV, or a light bulb or a loaf of bread from a shop, what considerations guide your purchasing decision? Functionality, price and appearance play an important role for most people. However, taking a second look, there is a whole chain of processes extending both upstream and downstream from the product in the shop. For example, in order to produce the TV, raw materials must be extracted, processed and manufactured. It is then delivered to the shop, and transported on to the consumer. Once in the home, it uses electricity over a number of years. Once the TV has reached the end of its service life, it becomes waste – waste – to be recycled, reused or sent to landfill.

This way of thinking is called life cycle thinking. Environmental life cycle thinking is concerned with the environmental impacts of products and services from cradle to grave. In other words from extraction of raw materials all the way through to the return of these materials to the Earth. This approach has formed the basis for development of the environmental management tool Life Cycle Assessment (LCA).

Applying this life cycle approach to environmental assessments means we recognise what happens at each of these points so we can balance trade-offs and positively impact the economy, the environment, and society.

This section introduces some key ideas and terminology relevant to the work of LCANZ members:

- What is LCA?

- Definition of life cycle assessment

- Elements of a life cycle assessment

- Applications of LCA

- Associated Terminology

What is LCA?

Life Cycle Assessment (LCA) is an analytical tool for the systematic and quantitative evaluation of the environmental impacts of a product or service system through all stages of its life. LCA takes a whole life cycle “cradle to grave” approach, in line with Life Cycle Thinking described above. A number of other environmental assessment tools are restricted to the production process, which is sometimes called “gate to gate” or, in the case of embodied energy cover the life cycle from “cradle to gate” without taking the end of life into account.

Definition of life cycle assessment

ISO 14040 defines LCA as:

“… a technique for assessing the environmental aspects and potential impacts associated with a product, by

- compiling an inventory of relevant inputs and outputs of a product system;

- evaluating the potential environmental impacts associated with those inputs and outputs;

- interpreting the results of the inventory analysis and impact assessment phases in relation to the objectives of the study.

LCA studies the environmental aspects and potential impacts throughout a product’s life (i.e. cradle-to-grave) from raw material acquisition through production, use and disposal. The general categories of environmental impacts needing consideration include resource use, human health, and ecological consequences.”

Elements of a life cycle assessment

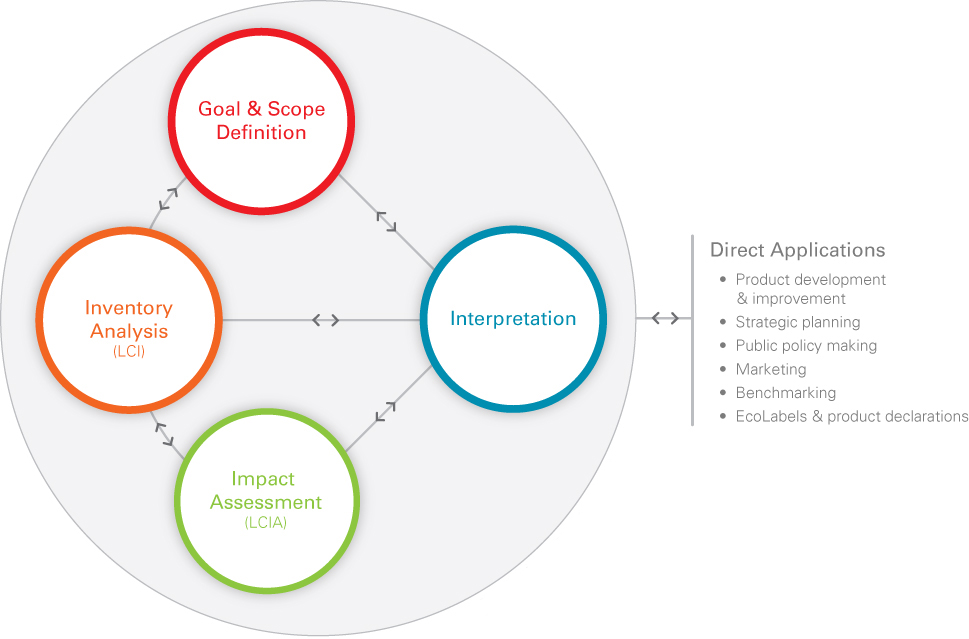

An internationally accepted framework for LCA methodology is defined in ISO standards 14040 and 14044. These standards define the generic steps which have to be taken when conducting an LCA.

Four different phases can be distinguished:

- Goal and Scope Definition: The goal and scope of the LCA study are clearly defined in relation to the intended application.

- Inventory Analysis: The inventory analysis involves the actual collection of data and the calculation procedures. The relevant inputs and outputs of the analysed product system are quantified and modelled.

- Impact Assessment: The impact assessment translates the results of the inventory analysis into environmental impacts (e.g. global warming, ozone depletion, acidification, depletion of resources, eutrophication etc.). The aim of this phase is to evaluate the significance of potential environmental impacts.

- Interpretation: In this phase conclusions and recommendations for decision-makers are drawn from the inventory analysis and the impact assessment.

These can be represented as shown in below. In practice, LCA involves a series of iterations as the scope of a study is often redefined on the basis of insights gained throughout the study.

Applications of LCA

In industry LCA is typically used for the design or improvement of products and processes. This may involve identifying environmental hotspots in production processes, but also considering upstream or downstream processes such as energy sources, product additives, end-of-life management options or by-products consumed in the product use phase. Comparative LCAs are commonly conducted to assess two or more differing systems that provide the same service. LCA results can also be used as part of an environmental management system to prove continuous improvement or for providing information for ecolabelling or environmental rating schemes.

In policy making LCA can be used for the development of product stewardship and circular economy strategies.

Associated Terminology

Associated terms are listed and explained on the Terminology page, and can also be accessed via the links below:

- Carbon Footprint

- Carbon Dioxide equivalent (CO2e)

- Greenhouse gas (GHG)

- Greenhouse gas accounting

- Life Cycle Assessment (LCA)

- Life Cycle Costing (LCC)

- Life Cycle Impact Assessment (LCIA)

- Life Cycle Interpretation

- Life Cycle Inventory (LCI)

- Life Cycle Management (LCM)

- Life Cycle Thinking (LCT)

- Water Footprint